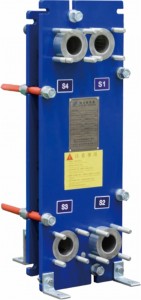

Heat Exchanger

Introduction to heat exchanger

Heat exchanger is a device that facilitates the process of heat exchange between two fluids that are at different temperatures. Heat exchangers are used in many engineering applications, such as refrigeration, heating and airconditioning systems, power plants, chemical processing systems, food processing systems, automobile radiators, and waste heat recovery units. Air preheaters, economizers, evaporators, superheaters, condensers, and cooling towers used in a power plant are a few examples of heat exchangers.

Heat exchanger are used to heat or cool a process fluid to a desired temperature by steam.It will influence the overall system efficiency and system size.There are many heat exchangers on traditional oil and gas or bulk chemical process plants, though they are less common in some other industries, such as food and pharmaceuticals.

The traditional standard type of heat exchanger is the shell and tube, though there are many variants of this design, and many other types of heat exchanger more suited to applications such as hygienic duty.

Advantages of plate heat exchanger

Plate heat exchanger has the following advantages:

● High heat transfer coefficient, making heat transfer efficiency high, less heat loss. The medium flowing in the platelets can form intense turbulence at low Reynolds number (Re), resulting in a very high heat transfer coefficient. On the one hand, the heat transfer efficiency of the plate group is very high, up to 1℃ temperature difference, very high energy up to 8600W/ m2.k; On the other hand, low energy recovery with high recovery rate can be achieved with low heat transfer temperature difference.

● Compact structure, small volume. On the one hand, it can meet more stringent and various types of equipment or system space design requirements; On the other hand, under the same equipment or system space design requirements, there is no need to reserve a large amount of maintenance space, such as excess space, can also be used to increase heat exchange.

● Flexible use, easy maintenance, simple cleaning. Just loosen the threads on both sides of the heat exchanger to achieve disassembly and assembly, on the one hand, according to the requirements of the working condition, flexible increase or decrease the heat exchange area; On the other hand, convenient inspection, maintenance, cleaning, saving users maintenance, replacement costs and time.

● Low cost and light weight. In the case of the same heat transfer, the use of heat transfer area is smaller than the tube heat exchanger, can effectively help users reduce costs.

Parameter information of plate heat exchanger

|

Tpye |

The clamping distance(mm) |

Width(mm) |

Transverse center distance (mm) |

Length(mm) |

longitudinal Center distance (mm) |

The bottom of the center Height to ground (mm) |

|

HS30 |

N(2.5+X) |

180 |

60 |

480 |

357 |

62 |

|

HS50 |

N(2.4+X) |

300 |

126 |

678 |

394 |

142 |

|

HS60 |

N(2.0+X)/N(3.0+X) |

320 |

140 |

920 |

640 |

140 |

|

HSL60 |

N(2.0+X)/N(3.0+X) |

320 |

140 |

1264 |

1036 |

137 |

|

HS100 |

N(2.55+X)/N(3.95+X) |

454 |

225 |

1045 |

719 |

183/200 |

|

HS100HL |

N(3.95+X) |

454 |

225 |

1380 |

1049 |

183/200 |

|

HSL100 |

N(2+X)/N(3+X) |

480 |

225 |

1888 |

1338 |

262 |

|

HS150 |

N(2.5+X)/N(3.95+X) |

610 |

298 |

1815 |

1294 |

275 |

|

HTS200 |

N(3.95+X) |

740 |

360 |

1400 |

698 |

354 |

|

HS200 |

N(2+X)/N(3.95+X) |

780 |

353 |

2260 |

1478 |

380 |

|

HS250 |

N(2.6+X)/N(3.95+X) |

920 |

439 |

2895 |

1939 |

435 |

|

HS350 |

N(3.3+X) |

1150 |

596 |

2882 |

1842 |

470 |

|

Tpye |

Very large mounting size(mm) |

The interface size(mm) |

Very large number of pieces |

Very large Flow (m3/h) |

Design Pressure(Mpa) |

|

HS30 |

500 |

32 |

95 |

18 |

1.0 |

|

HS50 |

1200 |

50 |

200 |

36 |

1.0 |

|

HS60 |

1200 |

50 |

250/203 |

36 |

1.0/1.6 |

|

HSL60 |

1200 |

50 |

250/203 |

36 |

1.0/1.6 |

|

HS100 |

1600 |

100 |

278/180 |

140 |

1.0/1.6/2.5 |

|

HS100HL |

1600 |

100 |

278/180 |

140 |

1.0/1.6/2.5 |

|

HSL100 |

3000 |

100 |

400 |

140 |

1.0/1.6 |

|

HS150 |

3000 |

150 |

600 |

360 |

1.0/1.6/2.5 |

|

HTS200 |

3000 |

200 |

400 |

600 |

1.0/1.6/2.5 |

|

HS200 |

3000 |

200 |

400 |

600 |

1.0/1.6 |

|

HS250 |

3000 |

250 |

500 |

750 |

1.0/1.6/2.5 |

|

HS350 |

4800 |

350 |

700 |

997 |

1.0/1.6 |

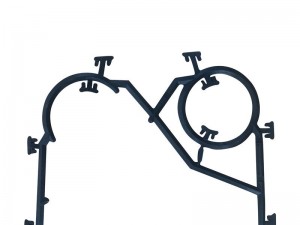

| Type | Size(mm) |

| M3 | 429*125 |

| M6B | 748*248 |

| M6M | 748*248 |

| M10B | 873*371 |

| M10M | 875*371 |

| M15B | 1500*498 |

| M15M | 1500*498 |

| M20B | 1747*621 |

| M20M | 1747*620 |

| MX25B | 2247*746 |

| MX25M | 2247*746 |

| M30 | 2245*995 |

| FTS6M | 510*329 |

| FTS20M | 961*621 |

| FTS6L | 690*329 |

| FT5M | 642*192 |

| FTL6B | 1148*248 |

| FTL10B | 1499*371 |

| FTL10P | 1499*371 |

| FT20M | 1745*620 |

| FT20P | 1749*621 |

| FT20B | 1749*621 |

| FTL35B | 2598*998 |

| FTL15B | 498*2250 |

| P16 | 427*123 |

| P26 | 709*248 |

| P36 | 1124*400 |

| A15B | 1552*587 |

| AK20 | 1215*664 |

| A35 | 2290*1210 |

| FT20S | 1740*616 |

| FT45M | 2996*1246 |